Welcome to TABS II

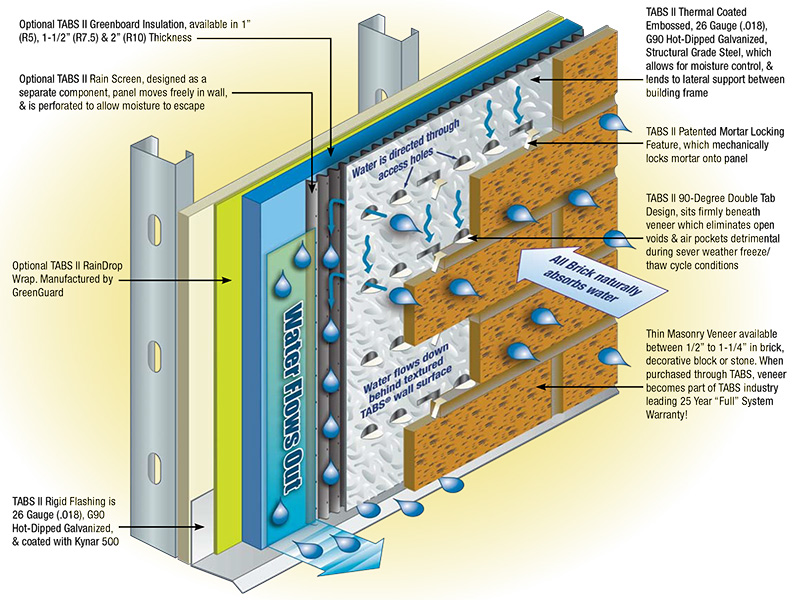

The TABS Wall Systems have been designed to address concerns that have punctuated the long history of adhered veneer installations.

In today’s construction market, the use of lath and mortar installation methods still dominate due to low costs of materials, despite actual higher installation costs and restrictions on building heights, veneer weights and limited or non-existent warranties. Recent developments of polymer mortars have improved methods of installations that rely solely on adhesive strength, but have similar restrictions regarding building height and veneer weight.

There is also the continued use and introductions of new panel brick systems with pre-applied veneers over a variety of boards including fiber, wood and cement. While seemingly practical and efficient versus field applied methods, there is a track record of failures in the 10-20 year functional life spans of such systems. Additionally, there is very limited certified independent test data for such methods.

TABS Wall Systems combines adhesive and mechanical support for veneers while also offering certified independent test data and long term warranties for all components of the installation.

The TABS Wall Systems Advantage!

We invite you to review our test reports, our installation guides & videos, our photo gallery and all the pertinent information in our Resources link.

Find out why these thin veneer manufacturers not only promote the TABS Wall System, but also stock and/or resell our products with their masonry products:

- Endicott

- Pine Hall

- Continental

- Watsontown

- General Shale

- Meridian

- H.C. Muddox

- Summit

- Cherokee

- Taylor

- Interstate

- Hebron

- Kingston Block

- Reading Rock